2009 Liebherr R916 excavator

Today, the German-Swiss multinational based in Bulle, Switzerland, is worth €16.404 billion (2023) and has over 130 companies, in 11 divisions, across 50 countries on all the continents of the world; and has a worldwide workforce over 53,000.

The divisions cover earthmoving/mining, mobile, tower and maritime cranes, machine tools & automation systems, aerospace & transportation systems, domestic appliances, and associated components. Concrete technology also resides within the companies portfolio of divisions, which very interesting as it isn't a mechanical machine. However, the world is quickly moving towards 3D printing concrete structures and Liebherr have already invested in their automation systems division too.

The company has remained entirely owned by the Liebherr family and has made them billionaires; as well as delivered Hans Liebherr the Frank P. Brown Medal from the Franklin Institute. Liebherr Group celebrated their 75th anniversary in 2024 and still pursue continuous development in the various fields it is engaged in; as well as being open to new technology and ideas. Something typified by the thoughts of Hans Liebherr: “My life has led me to consider that, with a strong will to do good work and fulfil different customer requirements to the best of your ability, you can also achieve goals that at first seem almost unimaginable. Don't allow yourself to be disheartened by set-backs, having faith can move mountains”

How was all this success is born out of a humble mobile tower crane?

Hans Liebherr founded his firm in 1949, in Kirchdorf, Württemberg-Hohenzollern, in the then West Germany. Post war Germany was desperate for reconstruction equipment, so much of it having sustained heavy war damage. A crane that could move would speed things up and Hans Liebherr, alongside a team of design engineers and tradesmen came up with the TK 10. The worlds first mobile tower crane. This new design, the first product out of the Liebherr Maschinenfabrik (engineering works), could be transported to, and set up on site, easily.

More than that, Liebherr could see the need for other machinery and tools for the building industry. Through the 1950s, Liebherr not only improved its crane designs but branched out in gear wheel manufacture for gear boxes, hobbing machines and, having experienced the inefficiencies of a cable excavator, designed the first hydraulic excavator in Europe - the L300. Liebherr's new machine is much lighter and considerably more powerful the cable excavator he had seen so went into production in 1954.

1954 was also the year Hans Liebherr hears of a refrigerator-making factory up for sale. After some business research Hans could see the potential of such appliances. He doesn't buy that particular firm but choses to build a new plant at Ochsenhausen and has refrigerators going out the door by the end of the year.

The range of construction machinery was expanded with the addition of machines to produce and transport concrete, then other forms of cranes for containers, shipyards as well as more specialist cranes. Alongside this continuous expansion in the construction type machinery came an expansion across Europe too. Facilities being built in numerous countries before the 1960s started.

The 1960s would see Hans Liebherr taking his business research of the 1950s aero industry into a more productive format. Liebherr-Aero-Technik GmbH was set up in March 1960. The plant in Lindenberg, Allgäu (Germany) to produce aeronautical items under licence but the real focus was always on developing prototype components in-house for the Aero industry. During 1996, that company becomes Liebherr-Aerospace Lindenberg GmbH.

Liebherr continues to expand its reach across the planet and into more and more industries and in 1977, through new technological innovations, presents the LTM 1025. A world's first as an all-terrain mobile crane. A telescopic arm rated to 25 tons allowed cranes to go where they could never go before. A concept taken even further with the LTM 1030.

Diversification has played a big part on Liebherr's success. Versatility, reliability, innovation and strength are also words that describe not only the products they make but also the company as a whole. Despite the years seeing change in the board as the family has aged, the Liebherr family remain firmly in control, building “Big machines for big tasks.”

The firm had sold its products but responding to economic condition also created a range of equipment, from mini excavators, compact loaders to power generators and compressors available through a rental program.

Liebherr R916 excavator

The Liebherr R 916 excavator range ran from 2009 through 2012. It weighs a whopping 24.1 tons! Certainly a “big machine”. It isn't a small crawler excavator in dimensions either, being 9.45m long, 2.98m wide and 3.057m high. It has wide tracks vital for off road work and a horizontal Boom Reach 9.8m. Not only is it a beast of a machine for excavation work with its detachable bucket system for different size options it also has other attachments that can be utilised for other sorts of other work too.

The main structure is robust, built from steel and forged components with X-shaped profiles that can give optimal stress-flow, rigidity and long life expectancy. The design gives great stability and a solid base for optimal traction and movement. Components not built by Liebherr themselves were all sourced within Germany and Switzerland so that quality assurance could be maintained. The Key-components however, where kept in house so the engine, electronic elements, hydraulic pumps, swing and travel gear boxes and motors, were all developed and produced by Liebherr.

The powerful drive unit had a state of the art engine control unit with a host of sensors in order to extract maximum efficiency in fuel consumption and output; and at all times conform with Stage IIIA /Tier 3 emission standards. Other clever points of attention included centralized lubrication points to reduce check times and ensuring all check points were accessible from ground level so all daily checks can be done quickly and in safety. In keeping with Liebherr's reputation for being particularly service-friendly, all aspects of maintenance and servicing of the R916 were considered in order to minimise “down time” spent in workshops. All work can be quickly accomplished because of well thought out accessible service points.

The hydraulic system works at and impressive 365 bar giving high digging and tear-out forces in the region of 121kN. Two pump circuits, to provide redundancy and allow for higher working pressure, can be run independently or coupled together for flexible energy utilization and power for the job in hand. Liebherr call it a positive control hydraulic system. They also ensured the operators control system was top notch too so the fast and precise supply of the hydraulic flow produced smooth superimposed movements and high precision working.

Another exceptionally well thought out place is the operator’s compartment. Cab design gives excellent visibility and is enhanced by an ergonomically designed seat and comfortable, sensitive controls. A colour touch display gives easy configuration of the machine and control of its working modes and optimization. As well as an overload alert system the cab has air conditioning and climate control to ensure the working conditions are always pleasant for optimal workmanship and efficiency.

In all ways this machine gave those that used it or the companies that operated it, state-of-the-art technology in all areas. High-quality workmanship across the board and absolute reliability and dependability. It is little wonder that Liebherr group has grown to such a dominant position in the construction machinery market.

The model

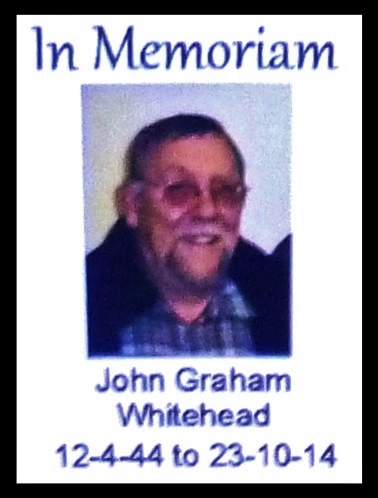

This model was built by our friend, and fellow IPMS (UK) Stafford branch member, Graham Whitehead. A particularly nasty form of cancer took him from us in 2014, but Graham passed on some of his models for safe keeping.

This one was scratch built by Graham a couple of years before he passed, he told us he once thought of having his own construction company and several of his models bear his name. Unfortunately he never got a chance to properly finish the base. This task was done by Ian at a later date.

The model holds a special place in our hearts, in memory of Graham. He was a lovely man and a great model maker.

RETURN TO:-