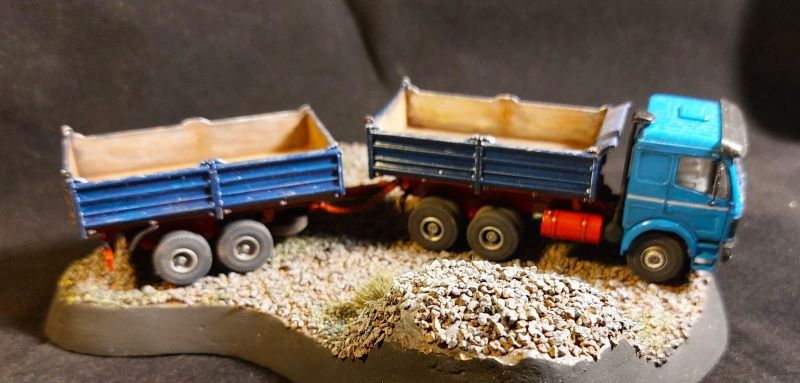

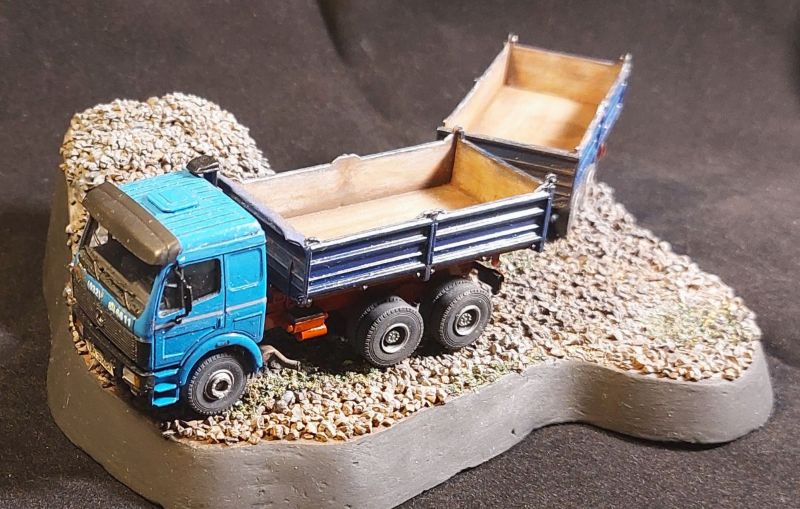

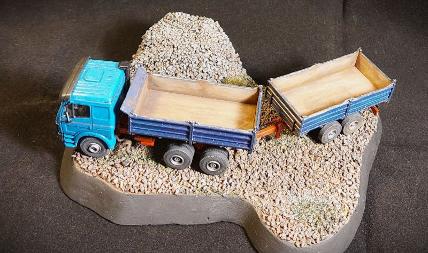

1995 Mercedes-Benz SK2544 chassis with Meiller-Kipper tipper body and Müller-Mitteltal tipper trailer.

The “SK” of the Mercedes-Benz SK series stands simply for Schwere Klasse "heavy class". That is to say Lorry models with a curb weight between 10,000–26,000kg. While Mercedes-Benz trucks were doing good business the world was beginning to wake up to the ecological dangers of fossil fuels and move towards countering expected laws from the increasingly lobbied political arenas of Europe. Mercedes needed to respond as much as anyone else and worked on upgrading their rigid trucks.

The SK series started as a reworking of the NG chassis with a better cab over the OM44X series engines, themselves and evolution out of the OM42X unit. New and advanced electronic driver aides and fault diagnosis were innovative the driver comforts meeting the highest of standards and OM44X series motors show shared many of the same design concepts of the earlier engines, some even going back even further. But they were cleverly reconfigured to meet omissions regulations introduced from 1992. However, while the detuning of engines reduced engine temperatures and emissions it meant they were far more thirsty on fuel; up to 10% more. But they remained solid and able to endure the extremes of climate and environment. Amongst the many engine upgrades were improvements to the cooling components/system and strengthening improvements to contain increasing engine pressure in order to tolerate higher engine loads.

The normally aspirated V6 OM441 engine produced around 224hp, the V8 OM442 yielded 290hp. The OM441 LA Single Turbo V6 gave from 220hp to 340hp with an intercooler. The twin turbo OM442LA V8 unit could put out 350hp and when fitted with an intercooler, as much as 500hp. Fuel usage was said to be 40Lper100km, the later Actros OM501La unit managed a fuel economy 37Lper100km well over a decade later.

To compensate for the heavier engines M-B moved from ZF cast iron transmissions to a 16-speed synchromesh Getrag aluminium gearbox. Two gear shifting systems were available, the conventional stick shift or a newly developed Electronic PowerShift (EPS) system. The semi automatic EPS transmission did allow the driver to worry less about the rev' matching needed, but the downside was a lack of reliability. Drivers liked it, but the truck owners and operators hated the repair bills and down time spent in the workshops instead of on the road.

SK series evolution of the 1973 “Neue Generation” trucks retained much of the looks of the earlier models but with some tweaks. Mostly in aerodynamic externally, ergonomically in the cab and the aforementioned engine/gearbox improvements. Produced between 1989 through 1998 they were reported as giving a much improved ride over the NG chassis.

As well as the naturally expected German manufacturing of the Mercedes Benz SK they were built in the far east. Ssangyong Motor in South Korea built them under licence calling them Ssangyong SY Truck this from 1993 until 1998. In China the BeiBen Powerstar was there licenced SK, but they used a Weichai WP10.380E32 engine over the M-B design.

MEILLER Tipper system

MEILLER, a family-run company since 1850, is based in Munich, Germany. It was founded by a blacksmith, Lorenz Meille, who already had three smithies in the area when he created MEILLER. On the 1st of June 1853 Munich’s Au district approved his hammer mill and armoury on Lilienstrasse, and another facility would be added to the list.

Within a few decades Lorenz Meille's firm had broadened its expertise to supply forged building equipment and winches for use in the forestry industry. This in turn, led to the firm creating a structure with a winch operated tipper system which could be mounted on a truck, and they gave the world the first trailer specifically for an "automobile truck" in 1907. Orders boomed from Europe and as far afield as Brazil requiring yet another new production facility to be built.

Lorenz Meille passed control of the firm to his nephew Franz Xaver Meiller and his work brought the firm to the attentions of Prince Regent Luitpold of Bavaria, which resulted in the appointment as Königlich-Bayrischer Hof-Werkzeugfabrikant (Toolmaker to the Royal Court of Bavaria). Franz Xaver was later given the title Kommerzienrat, meaning Commercial Counsellor, too.

After World War One, MEILLER continued to succeed and bought another factory. This time on Hindenburger Strasse (now named Landshuter Allee), in Munich. Designs continued to develop and tippers and trailers moved on to have new rack-and-pinion winches. Followed by MEILLER obtaining a DRP international patent for the first hydraulically powered three-way tipper in 1924. This new design set new industry standards when it went into production in 1925.

WW2 resulted in around 70% of of Meiller's factories being destroyed. Like Mercedes-Benz, the support of the workforce was crucial in getting Meiller back into production; they must have done a great job as they gave us the first skip loader 1945.

The 1950s went well and included buying a majority share in Munich-Moosach railway wagon factory of Josef Rathgeber AG in 1956. In 1962 Franz Xaver Meiller stood down from his role and handed control of the firm to his son; Franz Xaver Meiller, (junior) Dipl.-Ing. Who continued to build the company's manufacturing range very successfully through the 1970s. Meiller producced a list of achievements through the decade including the first hooklift system in 1972, “bordmatic” side wall design in 1973, improved semi-trailer hydraulics kits in 1975 and the first tipping semi-trailer in 1977. All of this meant yet another new building project with the firm creating its largest premises Rathgeber; which remains Meiller’s headquarters to this day. Production there slowly transferred to mass production of tippers.

Meiller continued to expand through the 1990s opening new production facilities in the Czech Republic and Austria, started took over MEILLER (SARL) France and developed IFE vehicle technology. New products include the 1997 Halfpipe rear tipper and the 1998 Bibenne, two-way tipper in France. In the new Millennium Meiller acquired Kögel Fahrzeugwerke's tipper product group in 2004. New products and designs have continued to flourish and Meiller opened more facilities abroad, including in Poland and Russia. In June 2017 Meiller also bought Boweld Truck Bodies Ltd. In Britain. The British tipper manufacturer gave Meiller and opening into the UK market and Boweld got access to Meillers tipping trailers, hook lifts and skip loaders.

From simple smithy to a globally active firm, MEILLER Group is at the cutting-edge steel component and trailer production, hydraulics and electronics. A “one-stop provider” for the haulage, tipping and waste industries, worldwide.

Müller-Mitteltal Tipper Trailer

Müller-Mitteltal is traced back to a blacksmith shop which Karl Müller took over from his father in 1929. He took the firm in new directions and produced their first all-steel long-log rubber-tired trailer in 1931 whilst also building a new vehicle factory.

Post war Müller rebuilt and created a special UNIMOG trailer set for off road use and in 1958 Müller-Mitteltal produced 5,000 trailers. The firm went on to design a series of tandem, truck, and low-loader trailers in the 1960s.

Müller-Mitteltal also makes custom trailers and equipment for the heavy goods and freight transport world, construction industries, waste disposal and recycling as well as municipal and the electricity companies at a “state-of-the-art” level.

The firm banks on its "Müller-Mitteltal quality" statement and collaborative approach to giving their partners what they want, not just the off-the-shelf options of others.

Mercedes truck with Meiller-Kipper tipper body and Müller-Mitteltal tipper trailer. This kit, #10814 (or #14122 depending on the boxing and catalogue), was the first Kibri street vehicle kit, way back in 1976; and it's still in the catalogue today, along with a huge range of vehicles. There are some fire service appliances as well as a very large amount of construction, farm and commercial vehicles, from across the eras. There are some cars, but the range is not nearly as big as the commercials.

A German manufacturer of high quality model railway accessories, Kibri was founded in 1895 in Böblingen, Württemberg, the historical German territory now the Federal State of Baden-Württemberg. Wilhelm Kindler and Adolf Briel set up their firm to produce metal toys branded as “Kindler und Briel GmbH”. The firm remained in Böblingen from 1895 up until 2007.

As plastic injection moulding gradually replaced metal for toy making Kibri moved into the 1950s producing some plastic model railway items. Sadly, the move from Böblingen to Schopfloch in 2007 didn't bring about success and the firm requested insolvency in July 2010. Viessmann Modellspielwaren, from Hatzfeld (Eder), then acquired Kibri in 2010, taking the rights to the Kibri brand name and the products. Adding this range to the Vollmer range created the extensive range of town and country houses, station, commercial and farm buildings, bridges and more from a wide era in time. And they produce other scenery items too.

There is such a huge selection for any modeller to choose from that Viessmann boast, “no two buildings on your layout need be the same.”

Ian acquired the kit at the Gaydon model truck festival in 2023. The box had extra items in it, and a few bits missing, so it appeared to have come from someone who built models and did a bit of kit bashing. Built largely from the box with just a few missing items having to be scratch built or added. It is painted with Alclad primers, Zero paints colours and Gloss coats. It was finished in September 2025.