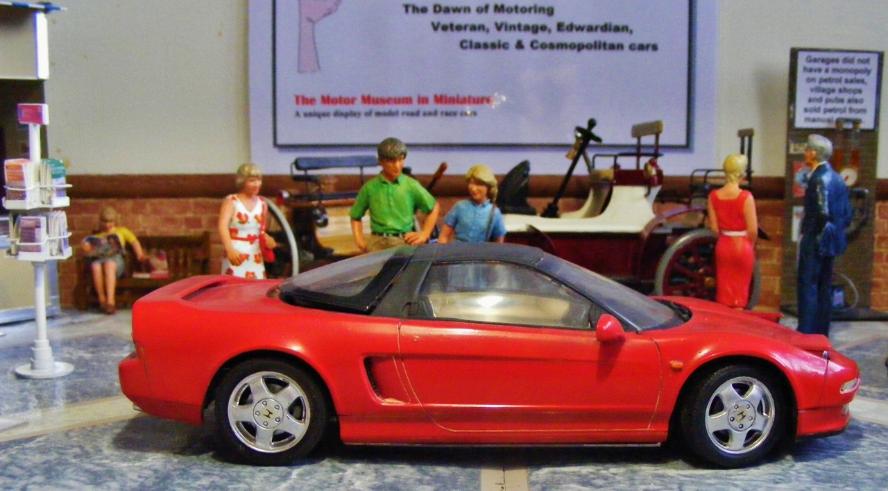

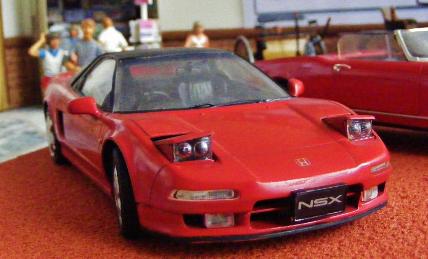

1989 Honda NSX

Pininfarina is now an historic and unforgettable name in motor car design. While Battista "Pinin" Farina himself died in 1966 the design studios he founded continued and although no longer under Farina family control, Pininfarina S.p.A. remains a much sort after company for designing cars to this day. Probably most famous for their connection with Ferrari, they have never been exclusive to them. So, when Honda decided to develop a futuristic sports car concept in 1984, they turned to Pininfarina for the body design. The Honda HP-X (Honda Pininfarina eXperimental) concept design was smooth, streamlined for aerodynamic efficiency. Honda’s input was to deliver a sports car that was fun, but also practical and straightforward.

Honda made a highly publicised return to Formula 1 racing in 1983. This prompted R&D staff, and coincidentally the Honda board, to think about producing a new road car with a potential to develop into a racing sports car. Project leader for the Honda NSX, "New Sportscar eXperimental”, Shigeru Uehara, said "It’s the dream of every development engineer to create a sportscar," and "I think the company wanted a car that could bridge its mass production FF models and F-1 cars." Uehara recalled, "They needed a car that would become the new face of Honda. Plus, we’d been contacted several times by those who were planning the Acura Division at American Honda concerning similar requests."

The origins of the NSX can be trace back to the 1984 HP-X concept, with the idea of a mid-engine, rear-wheel drive vehicle. Honda’s 1st experience with the rear engine concept, their mainstream models all used front-engine/front-wheel drive layout to provide superior comfort and space in the passenger cabin. It would take years, technological set backs and temporary suspensions before the concept became a design.

In what was a research led project, the concept of a two-seat, sports coupe grew. A low centre of gravity, smooth aerodynamic packaging, rear wheel drive sports based characteristics and a highly efficient 3Litre, V6 engine, intended to meet and preferably exceed, the Ferrari V8 engine performance of the period, were all examined, refined and perfected step by step. The R&D Centre began the basic research on a new drive layout for the new sportscar in 1984. The passions of Honda’s own development engineers was unleashed in the autumn of 1985 when the firm fully committed to the project.

As a company Honda are well known for their appreciation of the human being; the ergonomic and psychological blending of being and machine. The higher performance dynamic had to come with the assurance of human compatibility. Executive Chief Engineer Shigeru Uehara and Chief Designer Masahito Nakano wanted a car which would be straight forward for the driver to operate, exhibit adaptability to varying road conditions, offer reliability and be competitively priced.

The development staff were in consensus, in Shigeru Uehara's own words:

"To create a sportscar for a new era, we should balance human feelings and vehicle performance at higher levels. Accordingly, that car will represent Honda value; a benefit no one else can offer." Honda wanted a car “that provides superior performance yet requires equally superior driving skills in order to be controlled. We can then maximize the dynamic performance of this car to a degree that’s as close as possible to an F-1 machine."

Obviously the mid-engine design compromises cabin space and could make the car more difficult to control. For Honda, that was not acceptable as their philosophy, whether for their motorcycles or cars, was to hold the comfort of drivers and passengers to the highest standards.

The work of Pininfarina on the HP-X concept led to them being called in to work on the NSX body design. Advanced aerodynamics and European styling were one thing but the actual engineering of the monocoque body was equally advanced and impressive.

The weight issue was addressed with a new ideology for production road cars. Steel is heavier than aluminium, which in turn needs a larger and heavier engine to push it along. Both of which would push Honda's concept out of the midrange category. Aluminium also has other advantages such as corrosion resistance and being easy to recycle. However it also has disadvantages for use in production. It has a higher cost to work with due to being difficult to weld. Needing a specialist spot-welding machine to create the current required to heat and weld aluminium. The lighter metal is also more likely to buckle when used in stampings and deeply drawn press work. As such, the mass production of cars using aluminium was usually limited to a small selection of parts.

During the research into the viability of a totally aluminium monocoque body several staff made repeated journeys back and forth to the Waco and Tochigi R&D centres. It was during one of these trips that they realised that the Shinkansen bullet train they were travelling on was itself, largely, made of aluminium. This confirmed the concept to them, and their enthusiasm spilled over their partners in the Kobe Steel supply company. They had been working on many different formulas to meet the specifications Honda set out to overcome the production problems of welding, stamping, forming, coating etc. Each problem solved eventually led to Honda being the first manufacturer to produce an all-aluminium, monocoque body; albeit five different aluminium alloys. It saved around 140kg for the body alone while still being rigid and extremely strong.

This first Honda midship prototype body now required a series of tests to check the performance on the road, in crashes and in the strength and viability of repairs. On these results rested the fate of the NSX as a viable production sports car. The fact that there was a Prototype II tells us the results must have been good enough to push forward with, especially as the interior accessories and equipment were being fitted and the passenger comfort was being explored.

By February 1989 Honda's testing program was well advanced. A month of running test cars around the Suzuka Circuit provided a chance for a top F1 driver to give their opinion. Ayrton Senna was there testing the McLaren F1 car and as an engine partner the team took advantage of the chance to get Senna into the NSX. Senna's supersensitivity detected an apparent lack of rigidity, he told the development team: "I’m not sure I can really give you appropriate advice on a mass-production car, but I feel it’s a little fragile," he said.

With further work to be done on the chassis stiffness the testing moved on to the Nurburgring. 20.8km laps of 300 meters elevation change and more than 200 difficult corners, this notorious circuit is arguably the toughest test of a car anywhere. Honda R&D Europe (HRE) obtained the use of a base a couple of kilometres from the circuit at a town called Müllenbach. After setting up their new workshop the team started Honda's first ever overseas testing with the target of increasing their chassis rigidity. Their tests had been devised before hand and the Nurburgring was sure to highlight any deficiencies in vehicle response. Being so far from Japan meant the team, with the firms backing, had to come up with their own solutions to any problems they discovered. This they did sending data back to Honda's R&D Centre in Japan, for computer for analysis. By the end of the testing the engineers had increased the car’s rigidity by 50 percent while minimizing weight and effectively laying out the optimal shape for the NSX. Senna was back on hand again to test the NSX at the Nurburgring. His input this time helped with suspension tuning and handling. Aluminium suspension arms would eventually save an additional 20kg of weight.

After looking at their existing engines for a while, Honda decided to developed an entirely new, all-aluminium, 3Ltr, V6cyl' engine capable of 270hp. It would feature Honda's VTEC (Variable Valve Timing and Lift Electronic Control) system, titanium connecting rods, and was heavily influenced by the firms motorsport division; including collaboration from F1's legendary Aryton Senna.

The car was to have a manually operated 5-speed transmission but plans were made for the future SportShift, F-Matic, 4-speed automatic transmission, giving a conventional automatic system, or, fingertip manual shifting from a steering column mounted lever. This system became available from 1994.

Further testing in Japan and then the U.S. at the Laguna Seca circuit in California ordinary roads kept refining the design, which was gathering praise from test drivers and journalists alike. The NSX’s stability was praised, the comfort and ergonomics of the interior too. From advanced technologies to cutting-edge accessories the NSX had what the driver would want, electric power steering, power windows and full-automatic air conditioning, to that which which most would need, like traction control and 4-channel anti-lock brakes systems (ABS). Lead engineer Uehara said: "A car is a machine that functions through a direct link with the driver and passenger,". "The quality of that car is determined by whether or not the car can kindle excitement in the person who drives it."

A journalist said: "This car will change the standard for modern sportscars," and "All the cars we currently have are now history." Something that made the Honda development team very happy indeed. Eight months of strenuous effort, thorough attention to detail and deep collaboration with the motorsports division and even F1's McLaren team and driver Ayrton Senna at last produced a world-class sportscar. Dynamic performance in outstanding comfort, “the consummate integration between man and machine.” A prototype which Honda believed entrance driving enthusiasts everywhere.

After an extensive promotion campaign the NS-X prototypes where now in production as the Honda NSX for the most the world. Unveiled in February 1989 at the 81st Chicago auto show the Acura luxury brand would offer the Acura NSX from November 1990in North America. Acura would also be the branded seller in Hong Kong too. The domestic launch of Honda's new flagship NSX was at the Tokyo Motor Show, running from the 26th of October to the 6th of November, also to go on sale in Japan in 1990. Prior to these launches orders were already flying in and the purpose-built factory was in full production. After the launches it became clear the NSX was a massive success and before long a three year waiting list built up.

Production

As mentioned earlier building the car in all aluminium panels required specialist machines. This resulted in Honda building a new purpose-built factory; the Saitama Tochigi Plant.

Not only did Honda invest in the new technology and a new facility, they made new steps in staffing the building too. Positions were advertised throughout Honda looking for around 200 of Honda’s most experience and skilled personnel. Hand-picked expert engineers who had at least ten years experience across various Honda facilities were selected, with a special emphasis on those who had the understanding of the level of quality, handcrafted detailing required for manual finishing the aluminium materials. The new facility was not going to be a high production plant where the staff calibrated machinery, computers and robots. Here they were the computers and calibration tools. The priority was personnel over machines, something requiring the very best of the who wanted to build the NSX ,at a rate of only 25 cars a day.

At a ceremony in August 1990 the Honda Motor President, Nobuhiko Kawamoto, told the assembled staff and dignitaries:

"The NS-X is a next generation car incorporating many unique, proprietary technologies. Therefore, it represents the attainment of another dream for the Honda organization. And Tochigi Plant is where we will further that dream."

It's very easy, looking back, to say that the Honda NSX was a game changer in the world of production sports cars. Suddenly, a new benchmark was set, and it was far above anything anyone had ever envisioned. Looks, performance, and comfort? How can this be? There was always a compromise of comfort and driver specifications to meet performance and weight requirements. Now Honda had shot that that boat right out of the water.

Almost overnight the perceptions of customers and production car companies alike were flipped on their head. You could have startling performance, in comfort. You didn't have to give up your power windows to go fast. And you didn't have to pay through the nose either.

The top F1 design innovator of the 1980s, Gordon Murray, called the NSX "monumental" in terms of design, and, he says it was what inspired him to McLaren 'F1' sports car. In Murry's opinion, after having tested many different sports and performance cars, the NSX had the best chassis performance and would have been able to handle a more powerful engine. Murry's efforts to convince Honda to give the NSX more power were rebuffed, another reason he pushed for McLaren to invest in the 'F1' road sports car. However, the NSX remained "dear to his heart". He purchased one for his own use and covered for over 75,000 km; around 46,600 miles, driving it.

The real mark of success though, is sales. However you look at a car the proof is, does it do what it says it does. You can look at it, sit in it and enjoy the ergonomics and driver comforts; but is the super fast, high-performance car they say it is? To prove their point Honda created a racing version. And yes, it did what it said on the tin! In the end, and including all the continuous evolutions of the NSX, the car sold almost 8940 units.

Most importantly it remains a great looking car, on the road or the track, and is beloved by owners and fans alike.

Racing NSX-R

With the NSX sales numbers flying and the car proving to be a serious competitor to Ferrari and Porsche, Honda decided to push the envelope and go racing.

The NSX-R would need a serious set of performance-oriented upgrades and engineers began work on the obvious starting point for all racing cars; weight. Aggressive weight reduction created a much lighter body followed by the removal of items superfluous on a racing car such as sound deadening, air conditioning unit, audio systems, spare wheel and other electrics. Even the leather gear shift knob of the road car was replaced by a sculpted titanium one. The power adjusted leather seats gave way to Recaro carbon-kevlar racing seats, and, the standard forged alloy wheels were dropped in favour of much lighter Enkei forged aluminium wheels. Eventually some 120kg were taken away reducing the NSX-R to a healthy weight of 1,230kg.

Next step was suspension and braking upgrades. The NSX was prone to snap understeer, while rare under normal road conditions it was much more evident at high speed on the circuit. Some of this was cured with additional aluminium brackets to stiffen the chassis, but mostly it was reduced by an all new suspension with stiffer suspension bushings, anti-roll bars, springs and dampers.

Drive all that with a more powerful engine and the NSX-R becomes a potent machine which excelled on the track; even if the ride was jarring and noisy. Honda produced a limited run of 483 NSX-R machines solely for the Japanese market starting in late November 1992. Production stopped in September 1995.

This Tamiya 1/24 scale kit, # 24100, was 1st released in 1990, several later versions also added new parts to make later NSX variants.

The original kit is still on sale (as of 2021) and can be purchased for very reasonable prices; as little as £20! That is a great price for a very nicely detailed kit with full engine, suspension, chassis and interior detail. It is also an awesome looking car.

Tamiya have also released four racing NXS cars in some stunning colour schemes from around the world. The NXS-R, another stunning car.

Rod built the model in the mid-1990s. It is straight from the box and painted with Halfords acrylic car spray paints for the primer and body colour. Detail painting was done by brush with Humbrol, Revell and Citadel paints.

RETURN TO :-