After the ‘Emancipation Act’ British road systems became more organised and automotive vehicles proved their reliability in public transport roles. This soon meant local haulage and delivery started to become mechanised too, which started to eat into the railways trade. Thornycroft established a factory in Chiswick to make steam lorries, but the company was soon so busy that by 1898 a new manufacturing base in Basingstoke was opened. This allowed the company the space to build all manner of road going vehicles.

Nationally there were around 1,000 commercial vehicles on the roads in 1903 and the reliability of Thornycroft vehicles kept demand for the company’s lorries at a high level. The very wide variety of customer needs, from lorries to buses, proved that the large classes of commercial vehicles were here to stay. In fact in 1912 Thornycroft stopped production of their quality car ranges and turned production over to heavy vehicles only.

By 1916 petrol vehicles were listed for sale too. Thornycroft’s ‘Type J’ 4 ton lorry became famous for it’s durability and reliability in WW1 when the military made use of around 5,000 of the vehicles. By the time of the armistice in 1918 almost 1,500 people were employed by Thornycroft and it was continuing to grow. Commercial vehicles boomed in Britain so much so that by late 1924 the number of lorries, busses etc on the roads had risen to 300,000, the vast majority now being driven by petrol as diesel was yet to hit the markets. Around 40 British manufacturers and over 30 foreign firms were competing for sales in the petrol-driven commercial vehicles market.

When the general council of the Trades Union Congress called the general strike in support of miners in May 1926 the government responded by mobilising middle class volunteers and motor transport to minimise the effects of the frozen rail system. It proved to be a huge boon for the motor trade and many businesses realised the potential of transporting and delivering goods by road.

Thornycroft had become a huge and diverse company by 1926 with works in Southampton as well as Basingstoke with a product range motor vehicles to passenger ships, stationary and marine engines even motor boats with a top speed of up to 40 knots (74kph). As well as the two works plants, and a premises in London, Thornycroft had other branches around Britain and the rest of the world. On the 31st of July1926 Sir John E. Thornycroft told a meeting of the shareholders that the company had made a profit of £57,297 for the past year, £20,000 better than the preceding year. Sir John reported that commercial vehicle sales had increased and the 30-cwt lorry, originally designed for the military, was particularly successful.

Thornycroft listed their 4 ton ‘PB’ in October 1926. Especially designed for delivery work in towns, were space was restricted, it was designed with the cab virtually on top of the engine. This was termed the forward-control chassis which allowed the ‘PB’ a bigger load area than the earlier ‘KB’ despite being on the same 13ft (3.96m) wheelbase chassis and the overall length of the vehicles being almost the same. It was powered by the same 35hp 5.42 ltr HB/4 engine as the KB, a side-valve L-head engine which was easy to maintain and cheap to produce. It was a clever design with features common on our modern vehicles. A 4cyl’ monoblock casting with detachable head and crank case cover, and removable cam covers too. The crank shaft was mounted to the block with gunmetal shells and white metal bearings. This allowed inspection of the crank bearings by removal of the crank cover only making maintenance much quicker as the engine didn’t have to be removed from the chassis. The single cam used rockers and roller tappets to operate the inlet and exhaust valves, on the near side of the cylinder block.

Petrol was fed from the 26 gallon tank, positioned on the left inside the cab, to a very economical and flexible float-feed automatic type carburettor. Ignition was by automatic-control damp-proof high-tension magneto. The magneto was mounted on a platform on the near side of the crankcase and also helped supply power for electric lighting and electric starting. It even had an oil pressure gauge fitted, so the driver knew that the pump was working.

Cooling was through a vertical gilled tube type radiator of clever design that had removable top and bottom vessels to enable the quick and easy replacement of damaged or leaking tubes. A fan on the front of the cylinder block aided airflow through the radiator and a pump ensured even supply all around the engine.

Another modern feature was the putting the gearbox ‘in unit’ with the engine rather than as a separate box. By mounting the single asbestos fabric surfaced steel plate clutch and gearbox off the rear end of the crankcase perfect alignment of the transmission system is ensured so the left-hand gear changing was straight forward, despite the ‘invisible gate’ which was mounted directly on top of the gear-box. The lack of intermediate coupling rods also helped to keep gear changes smooth and positive. The speedometer and odometer were driven from the gearbox. All these design features helped the ‘PB’ reach a top speed in 4th gear of 21.6mph (34.8kph), more than sufficient for town and city centre delivery work.

Brakes consisted of the internal expanding type on the rear wheels, operated by a lever to the right of the driver. The foot brake operated an external contracting band on a 12in’ drum in the prop’ shaft. The lorry ran on cast steel wheels fitted with solid rubber tyres, so a top speed of 22mph was probably as much as the driver would want to experience anyway.

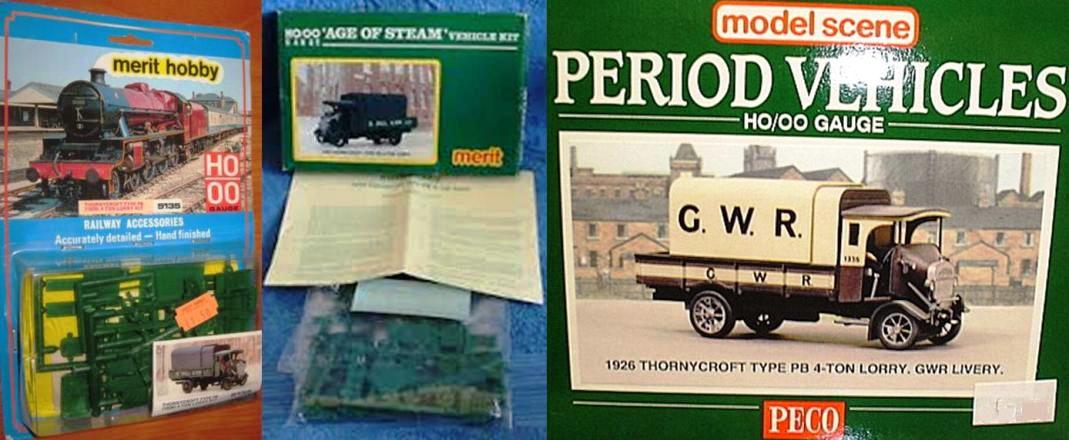

HO-OO scale Kit.

Built by Ian.

Ian Built this model in 2014 from the Peco boxing of this kit, #5136. The kit is actually a much older Merit kit from the 1970s aimed at the railway modelling fraternity. The detail level is good although not complete and the moulding is of variable quality. However the subject matter is interesting enough tempt Ian and the model built quite well.

This model was painted with acrylic hobby paints from the Art-Deco range applied with an airbrush. Detail painting has been done by brush applied Citadel and Art-Deco acrylic paints and washes. Ian has added scratch built parts and done a lot of work bringing the kit up to date. fine wire handles were added to the lamps, and used for the roof supports. Wire was also used for the retractable tilt hoops. The rear light is scratch built as is the starting handle and the fixed tilt curtains. All the lamps were drilled, given lenses with p.e. rings. Even the driving controls have been scratch built or modified. The red lining is from a Kangaroo decals set. In truth this model took a lot of hard work, due to the detailing work rather than any complexity of the kit, but the end result speaks for itself.

RETURN TO :-